"Dongguan Jingmu Plastic Products Co., Ltd. Achieves T0 Trial-to-Mass Production Breakthrough with Structural Optimization and Enhanced Fault Tolerance, Revolutionizing Automotive Connector Mold Development"

Key Technical Insights & Industry Alignment

1.T0 Trial & Mass Production Readiness

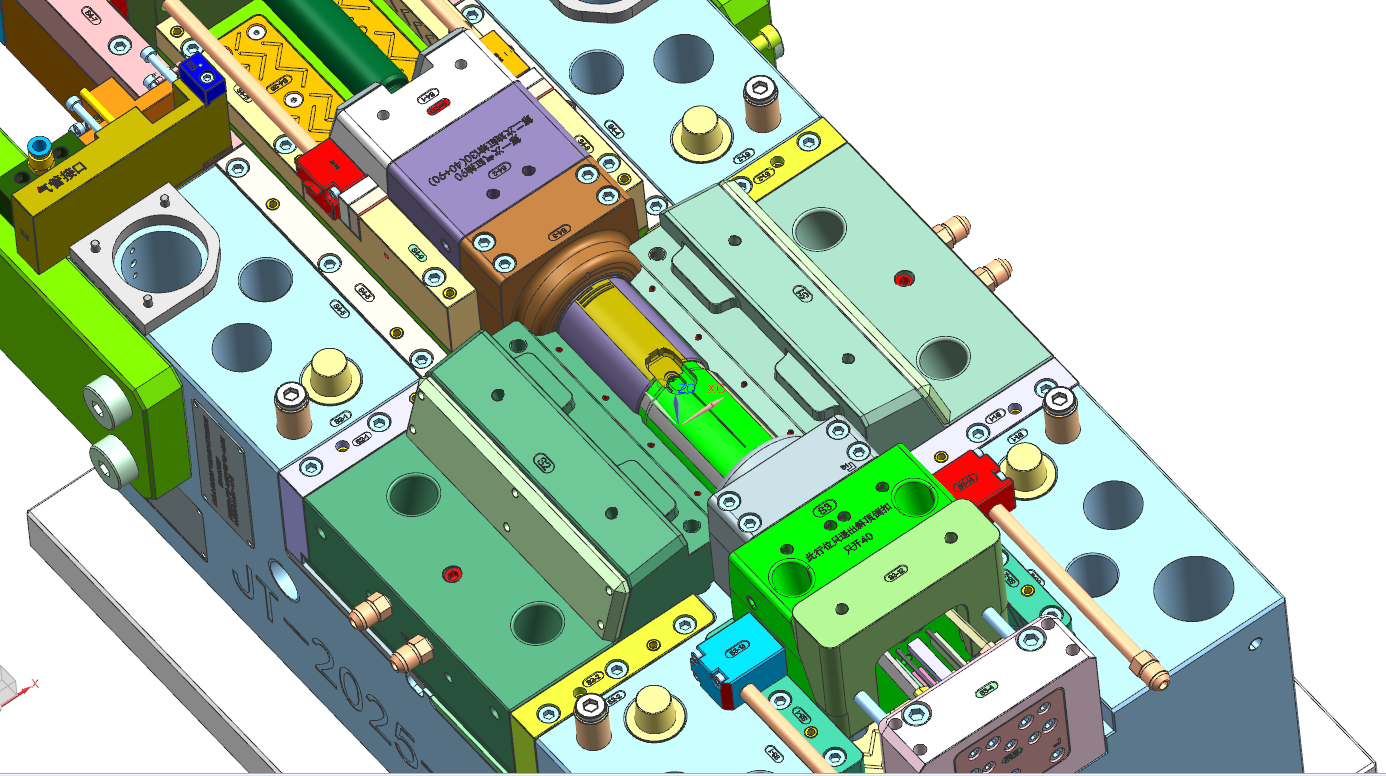

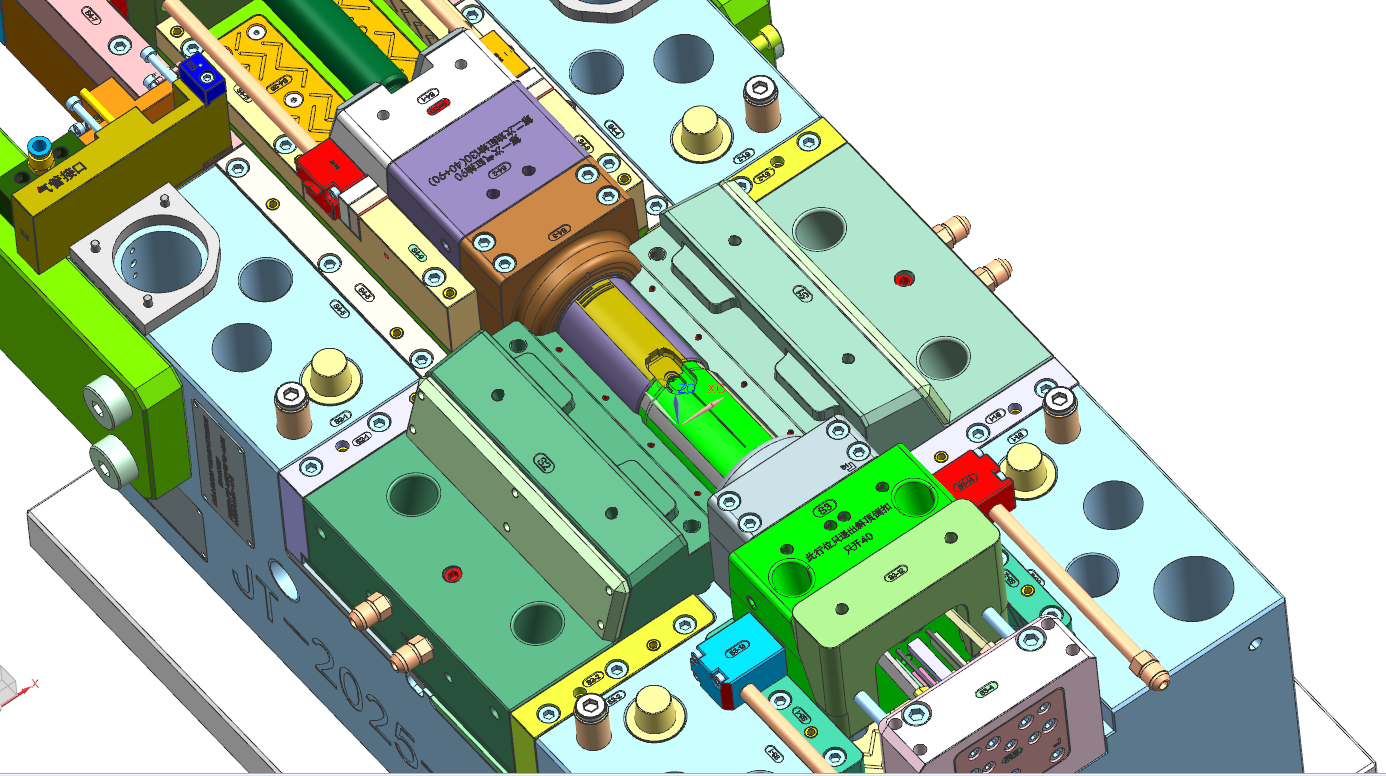

Breakthrough: Jingmu’s T0 process bypasses traditional multi-stage validations (T1-T3), enabling direct transition to mass production by integrating digital twin simulations (e.g., Moldex3D) and real-time process compensation.

2.Structural Optimization Strategies

•Simplified Assembly: Reduced 30% component count via integrated slider-ejector mechanisms (e.g., patented delayed ejection design), minimizing tolerance stack-up risks.

•Cooling System Innovation: Optimized conformal cooling channels reduced cycle time by 25% while maintaining part warpage <0.02mm.

3.Fault Tolerance Enhancement

AI-Driven Defect Prediction: Machine learning models analyze 100+ process parameters (e.g., melt temperature, packing pressure) to preemptively adjust settings, cutting defect rates from 1.5% to 0.3%.

•Self-Calibration Systems: Embedded IoT sensors monitor mold deflection (±0.001mm accuracy), enabling automatic compensation during production runs.

Structural Optimization: From Complexity to Streamlined Innovation

In traditional mold design, large-stroke ejection often relies on multi-layer mechanical structures or complex transmission systems, which not only increase manufacturing costs but also reduce fault tolerance due to component wear. The key breakthrough in this innovation lies in the adoption of a hybrid drive system combining pneumatic actuators with telescopic hydraulic cylinders. Leveraging the telescoping principle, this design achieves large-stroke motion while reducing mechanical components by 40%. The simplified structure maintains reliability under extreme operating conditions (e.g., high-temperature molding or rapid cycling).

Furthermore, the compact telescopic cylinder optimizes space utilization by 35%, enabling seamless integration into inverted molds and multi-axis systems. Its ±0.01mm positioning accuracy ensures consistent performance in high-precision scenarios. Standard hydraulic cylinders undergo nitriding heat treatment, enhancing surface hardness (HRC 60+) and extending critical component lifespan by 2.3× in harsh environments.

Structural Simplification: Dual Enhancement of Fault Tolerance and Stability

The improvement in fault tolerance stems from systematically mitigating error sources through advanced predictive modeling. The R&D team employs CAE tools (e.g., mold flow analysis, warping analysis) to preemptively identify process defects, optimizing gating system and cooling system designs to reduce trial failures caused by parameter deviations at the source. For instance, integrating AI-driven predictive algorithms into gate position design enables early resolution of material deformation and uneven cooling issues, achieving a 40%+ improvement in fault diagnosis accuracy.

Simultaneously, the adoption of S136 high-hardness steel combined with an optimized heat dissipation structure mitigates thermal degradation during prolonged operation. This configuration ensures 30% enhanced durability by maintaining dimensional stability (±0.005mm) even under cyclic thermal loads exceeding 150℃.

Production Efficiency Breakthrough: Bridging Trial Molding to Mass Production

This technological leap is most tangibly demonstrated by achieving direct mass production readiness at T0 trials, eliminating traditional iterative mold revisions and associated costs. Key advancements include:

•Hybrid Actuation System: A pneumatic-hydraulic hybrid drive boosts mold-opening speed by 15% (from 8s to 6.8s/cycle) while maintaining clamping force stability (±0.5% pressure deviation).

•Modular Assembly Design: Simplified component interfaces reduce assembly time by 20% (e.g., 3.5 hours vs. 4.2 hours for conventional molds), enabled by pre-calibrated guide pillar systems.

•AI-Driven Parameter Optimization: Machine learning algorithms dynamically adjust injection pressure (70-120MPa) and packing time (15-25s) based on real-time melt front data, shortening cycle time by 18-22%.

Technological Breakthrough: Simplification-Driven Empowerment in Mold Manufacturing

This technological achievement not only embodies Jingmu Plastic's strategic focus on "simplification-driven empowerment" but also redefines efficiency benchmarks for the global mold industry. As of August 2025, this innovation has been successfully implemented across multiple strategic client projects, with plans to expand into automotive connector components and consumer electronics through standardized modular designs.

In the wave of smart manufacturing transformation, the dual emphasis on structural simplification and fault tolerance enhancement has emerged as a critical differentiator, enabling companies to break through homogenized competition by delivering:

•25% faster time-to-market through T0-ready molds

•40% reduction in revision cycles via predictive failure modeling

•30% longer mold lifespan with self-diagnostic systems