Crystalwood Mould: The Invisible Champion in Medical Manufacturing

In the medical manufacturing sector, which demands exceptional precision, reliability, and safety, Dongguan Jingmu Mould & Plastic Products Co., Ltd. (hereinafter referred to as "Jingmu Mould") has demonstrated remarkable vitality through nearly two decades of deep expertise and continuous technological refinement, along with strategic industry expansion. Since its establishment in 2005, the company has consistently prioritized the medical industry as a key strategic focus. Beyond investing in advanced Class 100,000 cleanrooms, it has also continuously refined technical solutions by serving diverse client groups to address increasingly complex medical product manufacturing challenges. As of 2024, the company holds 18 patents, underscoring its relentless commitment to technological innovation.

The core barrier of medical manufacturing: the dual challenge of precision and cleanliness

The manufacturing of medical products is different from ordinary industrial products, as it is directly related to human health and safety. Therefore, it has almost stringent requirements for production environment, process control, and product quality. Jingmu Mold has a deep understanding of the characteristics of this industry and has been systematically building its core capabilities in the field of medical manufacturing for a long time. One of the most critical investments is a 100000 level dust-free workshop with an area of approximately 600 square meters. Behind this seemingly simple number is a rigorous environmental control system. The workshop is equipped with a separate tubular feeding room, changing room, air shower room, automated conveyor belt, ultraviolet disinfection lamp, quality inspection room, and packaging room, forming a complete sterile production chain. This isolated production environment ensures that every step from raw materials to finished products is maximally avoided from microbial and particulate contamination, providing a basic guarantee for the safety of medical grade products. However, a clean environment is only an introductory certificate.

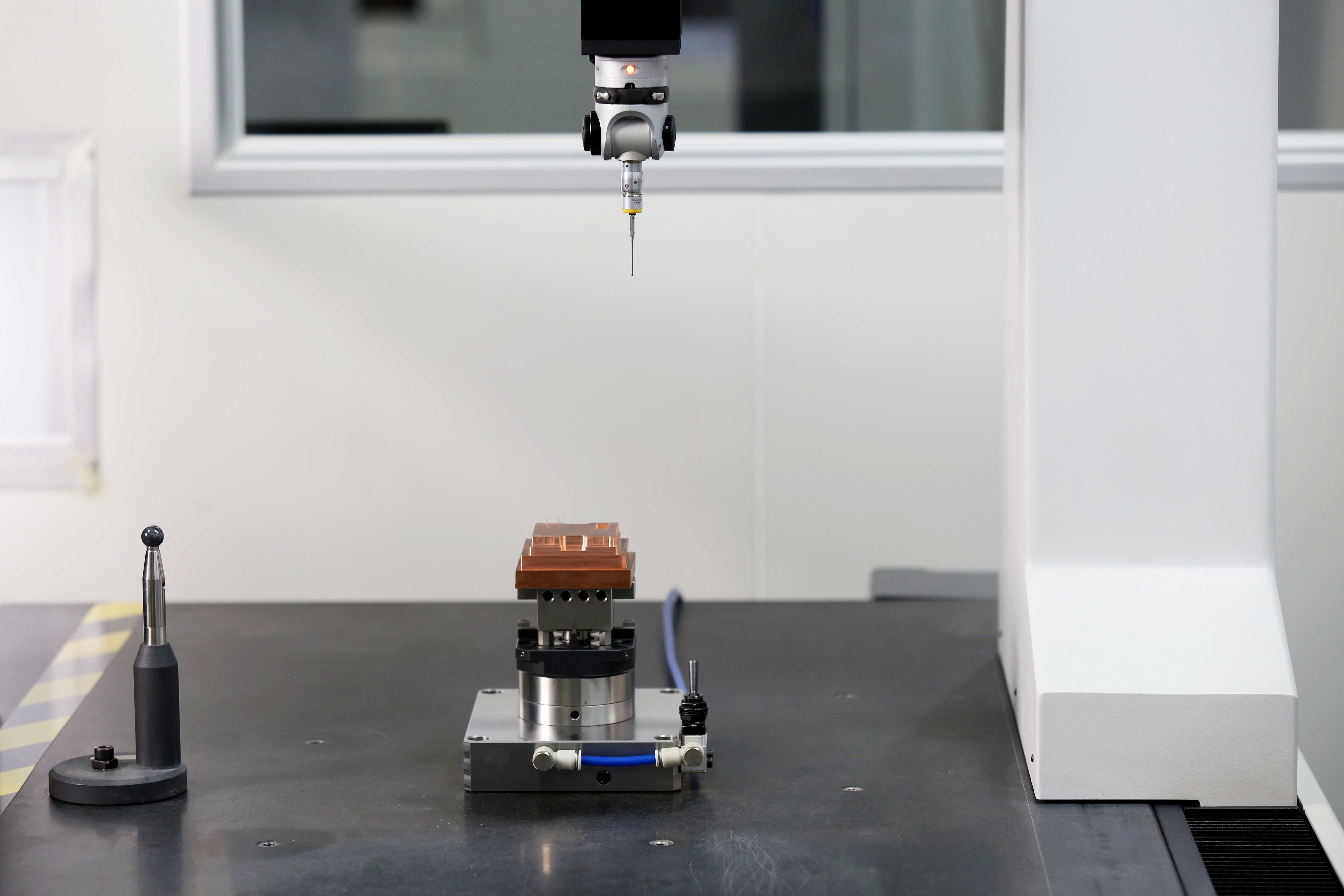

Medical equipment and components often have complex structures and precise dimensions, which place extremely high demands on the accuracy of molds and the stability of injection molding processes. Jingmu Mold has established an experienced technical and engineering team dedicated to providing customers with optimized mold design solutions, enabling products to be manufactured in a cost-effective manner. In the quality inspection process, the company has deployed 5 full-time inspectors and a series of high-end quality inspection equipment, including height rulers, colorimeters, 150x high-definition microscopes, fully automatic insertion and extraction force testing machines, semi-automatic image measuring instruments, and highly accurate Hexagon coordinate measuring instruments. These devices form a multi-level and comprehensive testing system, which can strictly control medical products from multiple dimensions such as dimensional accuracy, appearance quality, and material performance, ensuring that every batch of products leaving the factory meets design standards and regulatory requirements. The driving logic of technological iteration: polishing solutions in collaboration with diverse customers.

The advancement of Jingmu Mold's medical technology is not accomplished alone in a closed laboratory, but is constantly polished and validated through deep cooperation with numerous clients in different fields. The customer base served by the company covers a wide range of industries including healthcare, automotive, smart home, communication, mobile payments, security protection, and cleaning equipment. This diversified customer structure may seem scattered, but it actually provides valuable opportunities for the company to cross integrate technology. For example, the sensor packaging experience accumulated from the smart home industry may be applied to the design of medical device casings that require precise sensing; The signal shielding technology learned from the communication industry can be applied to the production of medical electronic products that have strict requirements for electromagnetic interference.

This cross industry technology transfer and innovation enables Jingmu Mold to provide customers with a complete set of non-standard customized processing solutions. The company adopts CNC machining and plastic injection molding processes, providing full process services from rapid prototyping, small batch production to large-scale production. Especially in the field of rapid prototyping, the ability of Jingmu molds enables medical equipment research and development enterprises to greatly shorten product development cycles, quickly carry out design iterations, and clinical validation. This agile manufacturing model is increasingly favored by medical innovation enterprises. More importantly, by collaborating with medical clients of different scales and needs, Jingmu Mold continuously deepens its understanding of specific challenges in the medical industry. For example, the ultimate requirements for cost control and large-scale production stability of disposable medical consumables; Strict control of biocompatible materials in implantable products; In vitro diagnostic equipment has dual requirements for structural precision and chemical corrosion resistance. In response to these diverse challenges, Jingmu Mold has continuously optimized its manufacturing process and quality control system, forming a technological advantage centered on lean production and agile processes.

Strategic Deepening and Talent Cornerstone: Building Sustainable Medical Manufacturing Capability

Expanding medical cooperation as a strategic priority means that Jingmu Mold needs to make long-term and systematic investments in technology, talent, and management systems. On the one hand, the company continues to invest in advanced quality inspection equipment and production facilities, and on the other hand, it also focuses on cultivating a high-quality team of employees and management through specialized training. For example, when recruiting quality inspectors, the company explicitly requires them to have the ability to operate precision instruments such as coordinate measuring machines and projectors, and be responsible for the accuracy and fairness of measurement data. This strict control over details is an indispensable cultural gene in medical manufacturing. From the perspective of the company's development trajectory, Jingmu Mold completed an important capital transformation in 2022, with the registered capital increasing from 200000 yuan to 2 million yuan. This measure not only enhances the company's capital strength, but also reflects its shareholders' confidence and commitment to long-term development. At the same time, the company also holds a 35% stake in Hangzhou Suijing Biotechnology Co., Ltd., which may be one of its strategic layouts to extend upstream and downstream of the medical technology industry chain, helping to gain a deeper understanding of medical technology development trends and customer needs.

Future prospects: Intelligent integration and industry empowerment

Looking ahead to the future, the expansion path of medical cooperation for Jingmu Mold is becoming increasingly clear. With the rapid development of emerging fields such as digital healthcare, remote monitoring, and intelligent diagnosis and treatment equipment, medical products are evolving towards smaller, smarter, and more personalized directions. This requires mold manufacturing enterprises not only to have precision machining capabilities, but also to have the ability to integrate cross disciplinary technologies such as electronics, software, algorithms, etc. The layout of Jingmu Mold in the research and processing of electronic products, as well as its accumulated experience in serving industries such as smart homes and communications, are well prepared to cope with this trend.

On the other hand, the regulatory framework for medical devices is becoming increasingly strict, with higher requirements for product traceability. The continuous investment in quality management systems and testing equipment by Jingmu Mold is aimed at helping customers meet these regulatory requirements. The company can further digitize and intelligentize its quality management, achieving full process data traceability from raw material storage to finished product delivery. This not only improves efficiency, but also provides strong data support for medical customers to pass regulatory audits。

By continuously cultivating the medical industry, Jingmu Mold is positioning itself not only as a component supplier, but also as a strategic partner for medical enterprises. The company is committed to providing production solutions for customers' products, helping them transform innovative ideas into safe and reliable medical products with higher cost-effectiveness. The foundation of this partnership is mutual trust and common growth, and Jingmu Mold is continuously consolidating this relationship by learning new technological solutions and improving manufacturing capabilities.

Against the backdrop of the sustained development of the global healthcare industry and the burst of innovative vitality in China's medical device industry, Jingmu Mold, with its solid technological accumulation, strict quality control, and open learning attitude, has promising prospects in the field of medical manufacturing. The company is located in Changping Town, Dongguan City, with a modern factory building covering an area of 6000 square meters. It is not only a production base, but also an important platform for continuous innovation and breakthroughs in future medical manufacturing technology. With the deepening of cooperation between the company and more medical industry partners, Jingmu Mold is expected to play a more important role in the medical supply chain in China and even globally, contributing the professional strength of manufacturing enterprises to improve human health. This strategic direction appears particularly clear and firm today in 2025.