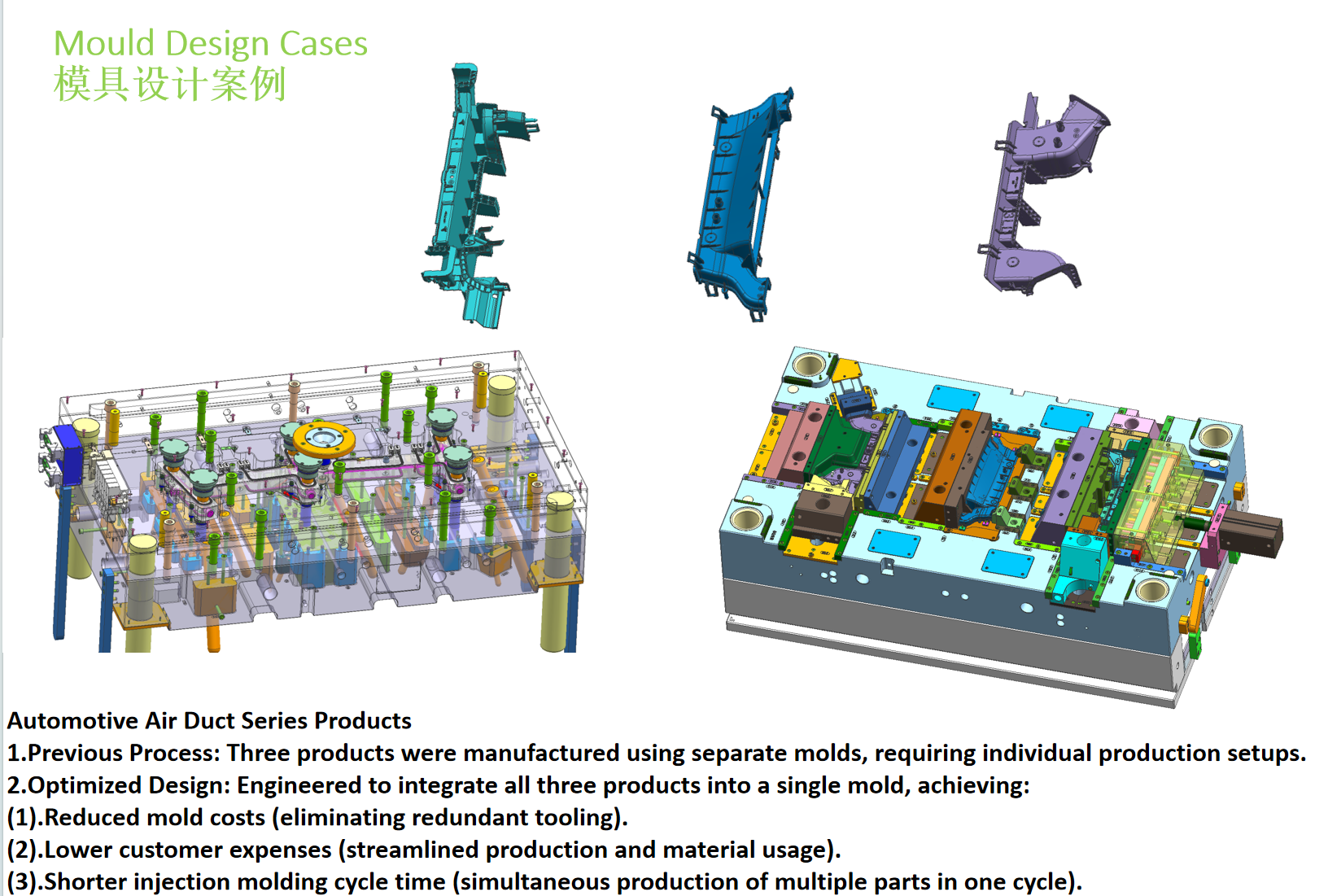

The image depicts innovative mold design solutions for automotive air duct components through modular integration. The presented system consolidates three previously separate mold sets , into a single composite mold structure. Key technical highlights include:

Multi-product Design

Utilizes in-mold insert integration and multi-cavity hot runner system

Achieves 3-in-1 production for diverse duct geometries

Optimized cavity layout with stepped arrangement maximizing XYZ spatial utilization

Reduces parting surface count by over 30%

Cost Optimization

Nested guide pillar structure reduces total mold weight by 22%

Development cycle shortened by 45% compared to traditional methods

Injection machine tonnage reduced from 350T to 220T

Overall product cost decreased by 38%

Process Reliability

Spiral cooling channels ensure uniform filling for PP+30% fiberglass

Dynamic temperature control: 82±1℃(moving mold)/78±1℃(fixed mold)

Micron-level exhaust slots (0.02mm depth) combined with vacuum assistance

Eliminates air traps and ensures dimensional stability

This modular design embodies lightweighting, principles, and parameterized modeling for >200,000 service life validation. It delivers cost-effective solutions for automotive part manufacturers requiring rapid multi-specification production transitions.