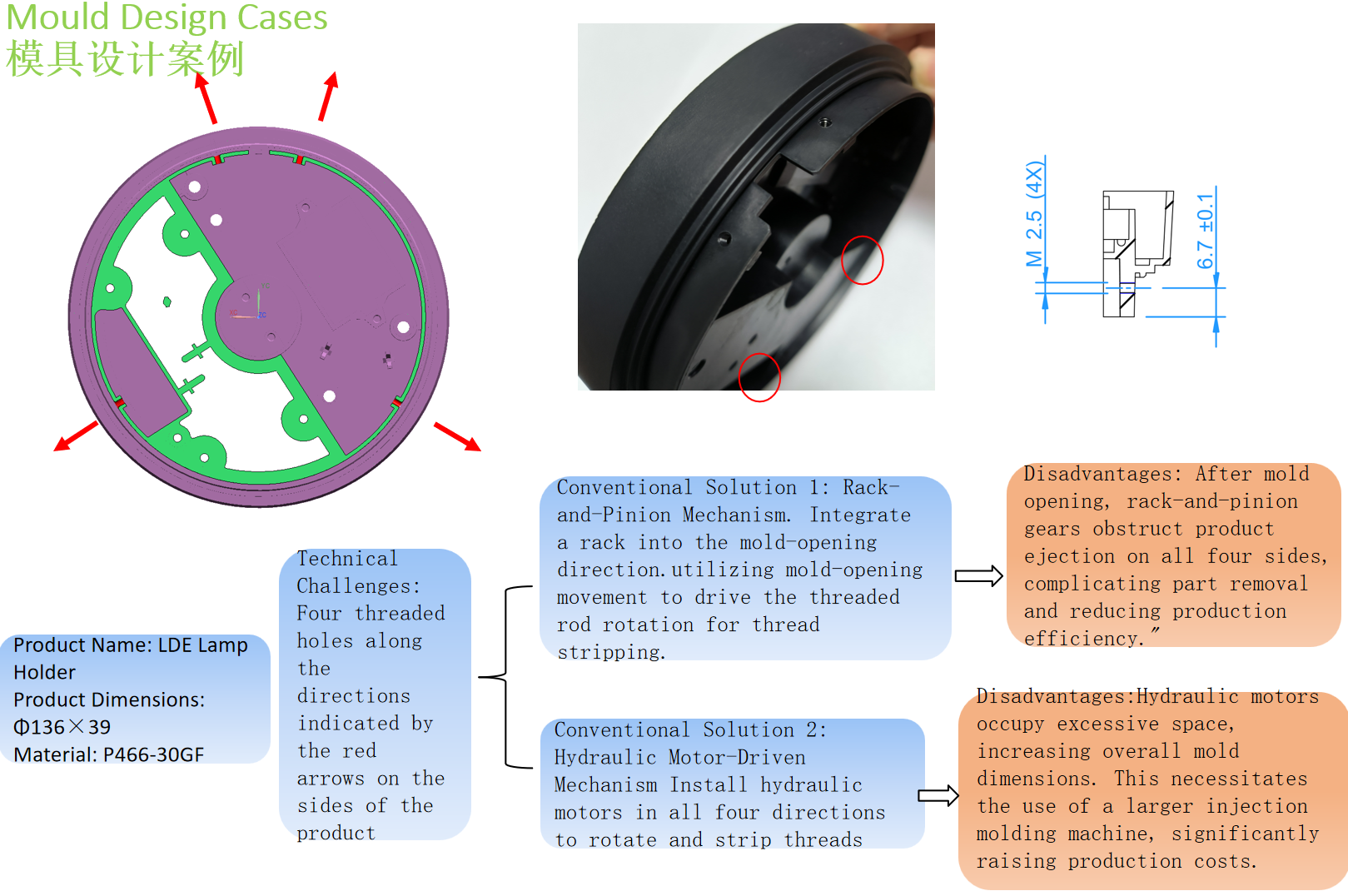

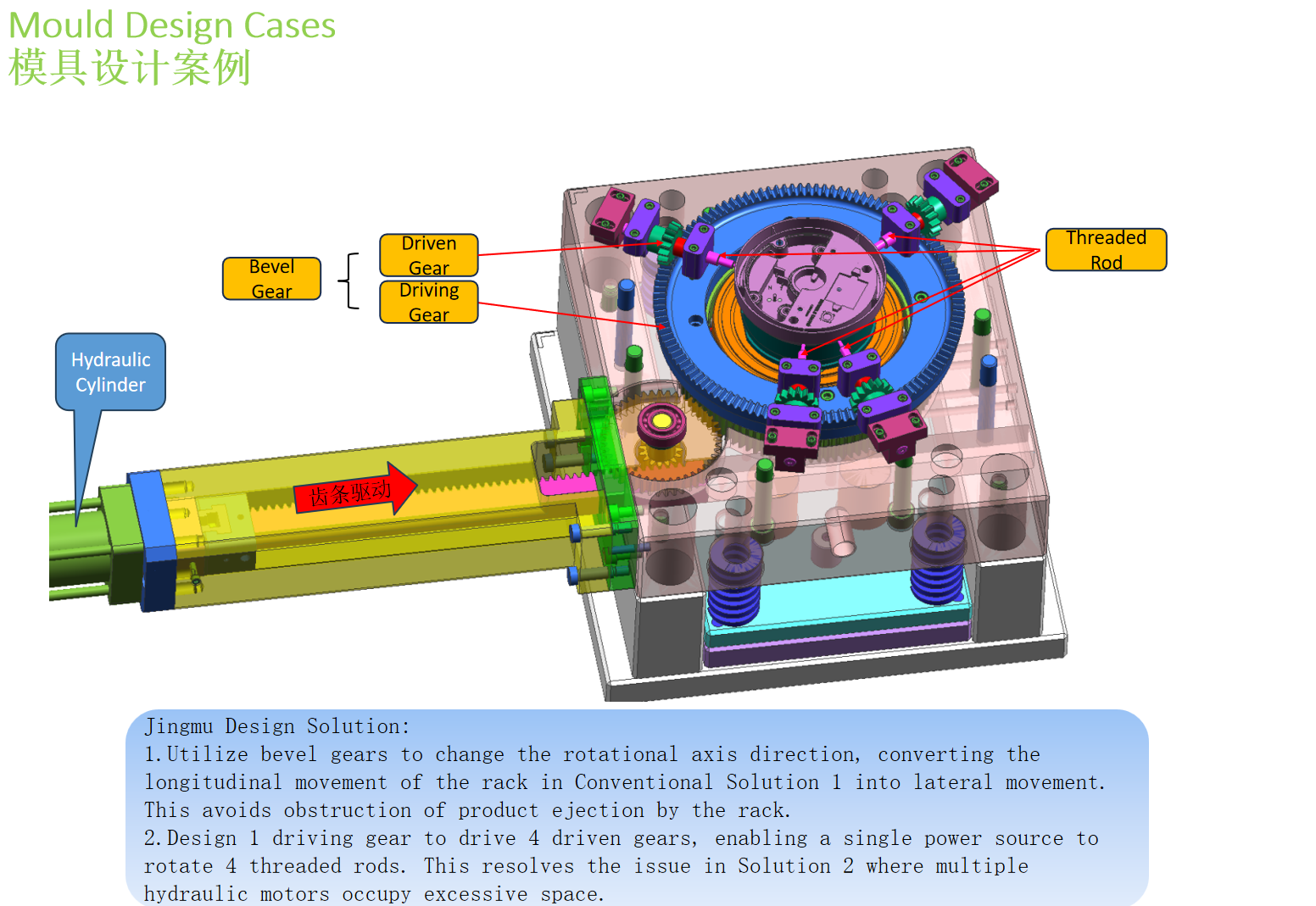

This mold design case presents an LDE lamp base forming solution using PA66-30GF glass-reinforced nylon material, with product specifications of Φ136×39mm. The critical technical challenge lies in achieving synchronized demolding of four circumferential M2.5 threaded holes. Two conventional approaches exhibit significant drawbacks:

·Rack-and-Pinion Mechanism: Utilizes mold opening stroke to drive rack rotation for thread stripping. However, peripheral rack interference around the product creates part ejection difficulties, adversely impacting production efficiency.

·Hydraulic Motor System: Incorporates four independent hydraulic motors for actuation, resulting in excessive mold dimensions (requiring large-tonnage injection molding machine compatibility) and substantially increased energy consumption costs.