Dongguan Jingmu Mold: Revolutionizing Smart Manufacturing Standards for 3C Products Through Precision Mold InnovationAs a pioneering leader in high-end mold manufacturing within the Guangdong-Hong Kong-Macao Greater Bay Area, Dongguan Jingmu Mold Co., Ltd. (hereinafter referred to as "Jingmu Mold") has built deep-rooted expertise in precision mold manufacturing, specializing in the R&D and production of automotive connector molds, 3C electronic consumer product molds, and precision connector molds. By spearheading technological innovation, the company addresses industry challenges head-on, driving the evolution of domestic precision manufacturing toward smart, high-end, and refined technical standards.

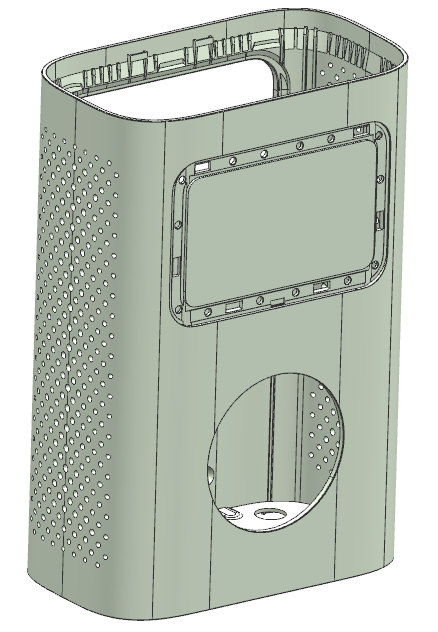

Structural Innovation in 3C Product Design: Four-Slide Combination Design and Process OptimizationTo address the high-density, miniaturization demands of 3C electronic products, Jingmu Mold employs a four-slide combination design with multi-directional core-pulling mechanisms, enabling single-shot molding of complex cavity structures. This approach significantly enhances mold structural rigidity and molding efficiency. In the thermal vent process layout, the company innovatively adopts a sequential core-pulling mechanism, prioritizing thermal vent ejection before mold release. This method effectively eliminates defects such as plastic part lifting and flash, achieving a qualified rate exceeding 99.5%.

Structural Innovation for Aesthetic Surface Joint Precision: Visual Seamless Joint Clamping System with Advanced Material Processing

To address the aesthetic surface joint precision challenges in 3C product manufacturing, Jingmu Mold has developed a Visual Seamless Joint Clamping System. This system integrates precision laser positioning and a zero-flash design standard, ensuring joint gap ≤0.01mm and completely eliminating surface protrusion defects.

Mold Core:

High-grade Mold Steel S136: Selected for the main mold structure, ensuring dimensional stability.

ASSAB Imported S136 for Slides: Enhanced with vacuum hardening + cryogenic treatment (-196°C liquid nitrogen quenching) to improve toughness and wear resistance.

Core Components:

Mirror Polishing & Nitriding Treatment: Achieves surface hardness HRC50-52+ on cavity surfaces, reducing friction and prolonging service life.

Mold Base:

Lung Kee Mold Base: Provides robust structural support, enabling an actual mold lifespan of 800,000+ cycles, meeting stringent mass production standards for premium 3C products.

Closed-Loop Process Control System: Sequence-Based Machining and Digital Precision Management

Jingmu Mold has established a sequence-based machining and digital precision management system, enabling full-process quality control with sub-millimeter accuracy:

In-Process Coordinate Measurement:

Utilizes Hexagon Metrology systems to perform ±0.005mm-level inspections on critical parameters such as slide machining accuracy and cavity dimensions.

SPC Monitoring + Thermal Deformation Compensation:

Real-time data acquisition dynamically adjusts toolpath strategies, compensating for thermal distortion errors (e.g., mold temperature fluctuations ≤±2°C).

Cumulative Tolerance Band Control:

Strictly limits tolerances on parting surfaces, assembly interfaces, and other core areas to ±0.05mm, ensuring geometric consistency.

Precision Polishing & Assembly Process:

Combines mold temperature balancing (±2°C control) with mirror finishing to guarantee dimensional stability within ±0.03mm for mass-produced components.

Successfully applied to 5G communication module molds for supply chain partners including ASUS and Midea, achieving:

48-hour rapid delivery cycles

Million-unit stable mass production with 99.95% yield rate

Dongguan Mold Industry Cluster Empowerment: Redefining Smart Manufacturing Standards

Leveraging Dongguan’s reputation as "China's Mold Capital", Jingmu Mold integrates regional industrial chain advantages in precision machining, surface treatment, and certification services to deliver a comprehensive end-to-end service ecosystem—spanning design optimization to mass production.

Defining Precision Through Technology, Establishing Standards With Artisan Mastery

Jingmu Mold will continue to deepen its expertise in precision mold manufacturing, leveraging innovative processes and digital control capabilities to propel domestic molds from "follower" to "global leader." The company aims to set a benchmark of "Chinese Precision Engineering" for the global consumer electronics and automotive industries.